Fibre Cement Cladding

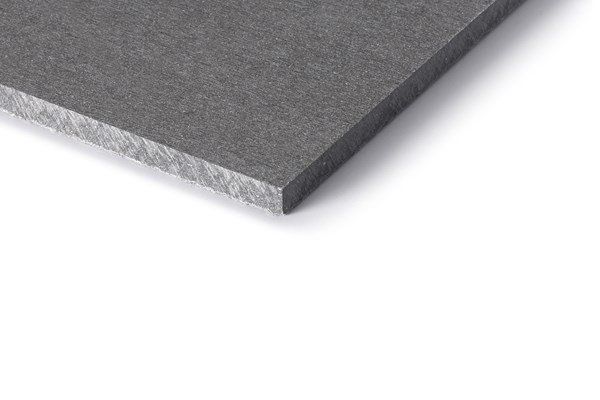

Fibre cement cladding boards

are made from natural materials: cement, mineral fillers and water, to which organic fibres

are added. With passage of time, the fibre cement boards

will age by patination, just like natural stone, giving the facade a natural look. The facade is virtually maintenance free with exceptional durability. The best advantage

of surface of the fibre cement boards

is their strong dirt, stain and water-repellent properties. They are also resistant to all types of weather conditions, namely frost and thaw, heat and moisture.

Fibre Cement Cladding - Available Range

Fabrication available

We work with you to come up with the very best solutions for your challenges!

01

Simple installation

02

Bespoke

03

Natural looking

04

Simple cutting

05

Durable & maintenance free

06

Eco friendly

07

Non-combustible

08

Value for money

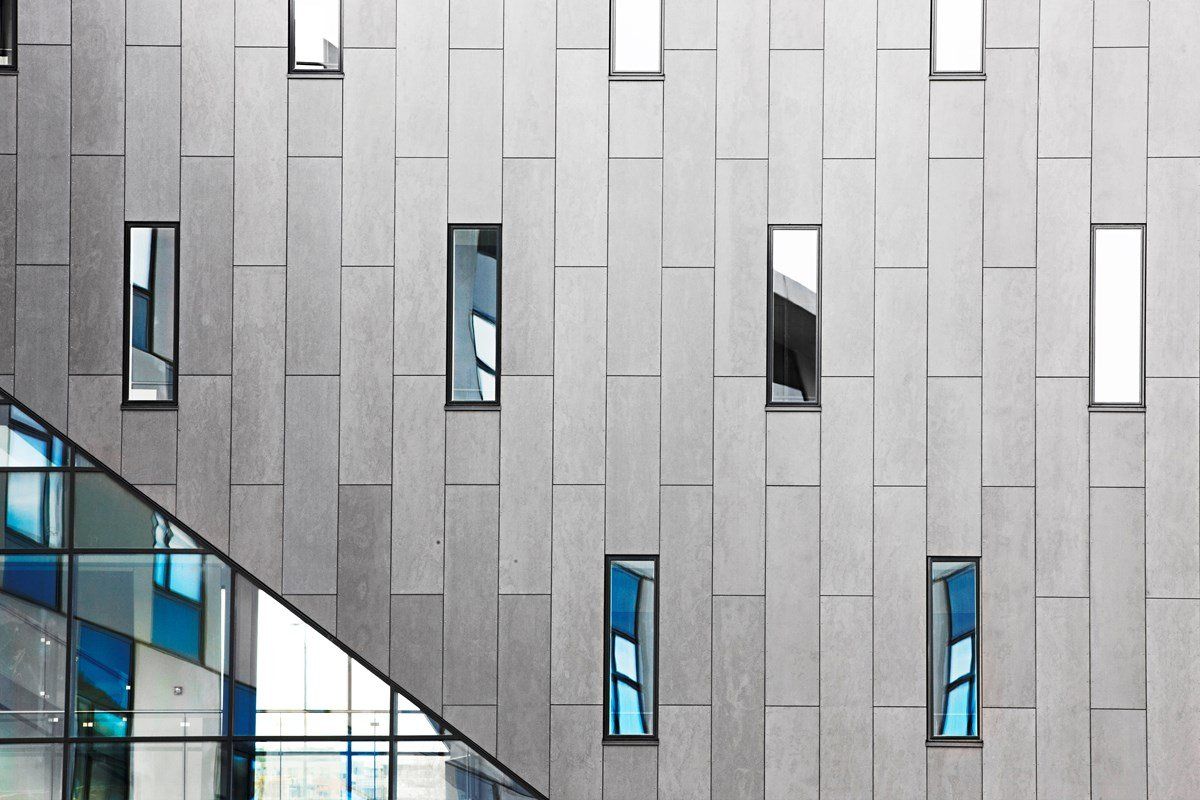

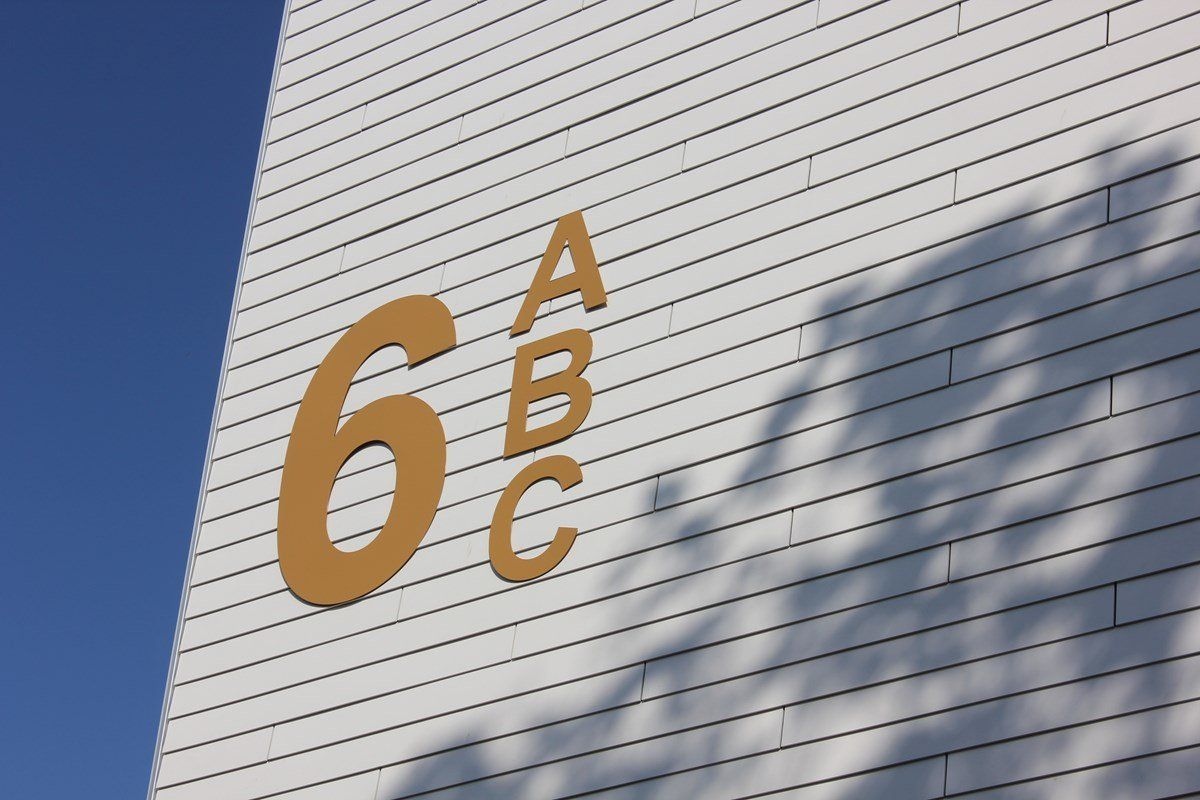

Fibre Cement Cladding Ideas

Frequently asked questions

- Can these stone cladding panels be installed both externally and internally?

Yes. They are mainly designed for exterior use, however can also be used on internal solid walls. Internally, they are not suitable for use on stud wall, unless they are fixed onto a cement board or MGO board. The panels were tested for thermal shock to ETAG 004:2013 and no damage was detected. They were also tested for frost damage and freeze-thaw according to ETAG 004:2013 and no damage was detected either.

- Are all the panels different?

The panels are of the same design and size, so 600 mm wide x 200 mm high, and 300 mm wide and 200 mm high. The thickness is up to 40 mm at the stone face. Weight is approximately 75-80 kilograms per square metre. They are different in colour and the individual pieces making up a panel also vary.

- Are the panels difficult to install?

Not at all. They can be installed even by a DIYer.

- What surfaces can the panels be installed onto?

They can be installed mainly on block work, and also on timber frame line with cement or MGO board as well as insulated concrete form. Each application has its own surface preparation. Please contact us for details.

- Do they require any sealing or maintenance?

No, they do not. They are virtually maintenance free and do not require sealing. However, sealing will do no harm, and can improve the resistance to contaminants, organic growth or elements. We also supply water-repellent sealers which do not affect the colour of stone, and sealers that create wet-look effect.

- Are they suitable for wet areas?

Yes, as a natural stone product they are. Please make sure you use correct adhesive.

- Are they resistant to heat?

The panels were tested for fire resistance and reaction to fire to EN 13823:2010, EN 11925-2:2010+AC:2011 and EN 13501-1 - they were classed as fire class A1 and non-combustible.

- What is the best way to cut them?

For dust-free wet cutting, use a wet tile saw. Angle grinder is a second best option as it creates dust. Please remember to use dust mask and glasses.

- Do these panels require any mechanical fixings?

Yes, they require secondary mechanical fixings at heights over 2 metres. The panels come with integrated fixing clips, all you need is appropriate bolts, screws or hammer fixings with plastic plugs depending on the surface the panels are getting fixed to, and they should be approved by a qualified structural engineer. Any fixings should be made of stainless or galvanised steel. Please contact us for advice if you are unsure.

Interested in Fibre Cement Cladding?

Call us at 020 4578 0824 or contact us for your free quote.

LATEST ON OUR BLOG

Real Brick Cladding are UK suppliers of interior and exterior brick slips and brick tiles , brick veneer as well as reclaimed brick slips & tiles and brick effect wall tiles. Brick cladding systems, brick panels , brick sheets , brick wall panels and stone cladding are also supplied.

DELIVERY INFORMATION | DAMAGE & WASTE

Real Brick Cladding is a trading name of Specify Ltd. Company Registered in Scotland

91 Westlaw Place Glenrothes KY6 2RZ

Reg. No. SC460581

VAT No. 172 4800 18

Specify Ltd - Stone & Brick Cladding:

www.specify-uk.com | www.realstonecladding.co.uk |

for EU sales contact:

www.naturstein-verblender.de |

www.kamien-elewacyjny.com.pl

CONTACT

T: 020 4578 0824

M: 0786 1111 231

91 Westlaw Place

GlenrothesKY6 2RZ

Get a Quote

All Rights Reserved | Specify Ltd